Striving for best-in-class industrial performance

A comprehensive approach to excellence

Our 360° lean manufacturing approach, the FORVIA Excellence System (FES), is designed to help us achieve best-in-class industrial performance. It integrates the best processes and practices from Faurecia and HELLA, incorporating digitalization and our sustainability roadmap. Rolled out to FORVIA sites since mid-2023, FES plays a key role in achieving both our financial POWER25 and scope 1 and 2 carbon neutrality targets for 2025. This is our way to execute and improve. It serves as the foundation for delivering safety, performance and total customer satisfaction.

Digital transformation; industrial application

Sustainable competitiveness

Executive Vice President, Group Industrial Operations, FORVIA

Allenjoie: a blueprint for Industry 4.0

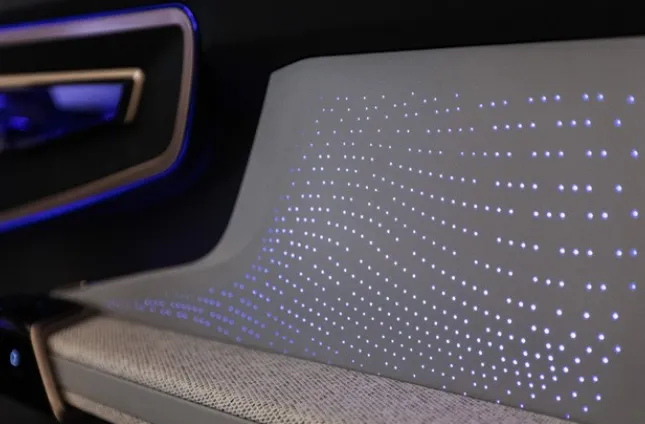

Inaugurated in 2023, the Allenjoie platform includes two major sites and is FORVIA’s technological flagship in France. One plant produces seating components at an unparalleled degree of digitization and automation, making it one of our most advanced facilities worldwide. The other is the first mass production site of vehicle hydrogen storage systems in Europe, and will support the evolution in transport from ultra-low to zero emissions.

Both plants are industry-leading examples of sustainable production, meeting the strictest environmental standards. The platform’s rooftop solar arrays, biomass-fired boilers, heater recovery and rainwater sanitation systems have earned it BREEAM Excellent certification — the first awarded to an industrial site in France.

Quality: a mindset of excellence

In the automotive industry, quality is not just a function - it’s a mindset. It means delivering excellence at scale, with the ambition of achieving zero defects.

Quality spans multiple dimensions: from perceived quality (design, comfort, finish) to compliance with technical, safety, and regulatory standards, and ultimately, to customer satisfaction across the entire product lifecycle.

At FORVIA, quality is embedded in everything we do. It requires discipline, rigor, creativity, transparency & a problem-solving mindset - every day. As the industry undergoes its most profound transformation since the invention of the combustion engine, our commitment to quality remains a cornerstone of our performance and reputation.

Quality as a Key Differentiator

In a highly competitive and complex industry, quality remains one of the few levers we fully control - and one of the most powerful ways to differentiate ourselves. While innovation is essential, quality is what builds trust, ensures safety, and drives long-term customer satisfaction.

To deliver quality in a rapidly transforming industry, we focus on:

Designing right from the start: Translating customer expectations into robust product and process designs, sometimes with multiple finish levels for the same part - all from the first try.

Flawless industrialization: Using standards and simulation to ensure smooth mass production with minimal waste and maximal consistency, across highly diverse and specialized sites.

Lifecycle quality management: Monitoring product performance throughout the product’s life, resolving issues proactively with tools like the 5Star app for real-time customer feedback and continuous improvement.

Our 5Star app enables real-time customer feedback, helping us stay proactive, transparent, and responsive. The application is currently being updated to meet our customers' new quality standards and to keep providing them with a seamless five-star customer experience.

We link Total Customer Satisfaction (TCS) and Quality because they are inseparable. A zero-defect culture is essential not only to maintaining strong customer relationships, but also to delivering long-term value.

Through digitalization and continuous improvement, we are setting new standards in quality performance and customer service - reinforcing our role as a trusted partner over time.

Group Total Customer Satisfaction & Quality Senior Vice President

Quality in action

Our expertise is structured around five key domains:

Customer Experience

Advanced Quality (Program & Engineering)

Supplier Quality

FORVIA Management System

Operations Quality

The deployment of FES is currently underway within our Engineering functions, following the CEO of FORVIA’s ambition to roll it out across all functions.

As vehicles become more complex, so do our quality demands:

Safety remains paramount.

Sustainability adds new constraints, requiring us to integrate bio-sourced and recycled materials without compromising performance or aesthetics.

Digitalization introduces new risks - especially with the rise of Software Defined Vehicles - requiring perfect alignment between hardware and software updates.

To stay competitive in a context of accelerated development cycles, we must detect and correct issues faster - even anticipate them. That’s why we invest in:

Advanced digital tools like thermal imaging and cross-site data analytics to detect anomalies early.

AI and GenAI to simulate product design and predict quality outcomes before production begins.

Our end-to-end Quality digital roadmap supports a shift toward proactive quality management, setting new benchmarks in performance, customer service, and operational excellence.

Various collaborations to ignite innovation inside the Group

Partnering with schools and institutions

Since 2022, we’ve participated in four EU-funded programs exploring sustainable composite manufacturing and circular approaches for automotive electronics. Our R&D teams engage with French engineering schools on polymers and mechatronics. We have also partnered with the University of California (Berkeley), the Indian Institute of Science (Bangalore), and Tongji University (China) for cutting-edge sensor development. In 2023, we started a four-year collaboration with CentraleSupélec (France) focusing on the automotive applications of artificial intelligence for sensor fusion.

Collaborate with industrial leaders and promising start-ups

We collaborate with a diverse range of players, from global industrial groups to promising start-ups with disruptive ideas identified through our scout network. In Berlin, we operate The Drivery, a mobility innovation hub with over 800 members, including 140 start-ups, and expanded this concept to China in 2023. These innovation ecosystems are crucial to meet scope 3 targets.

Activate technological players

We also strategically partner with key tech players – for example, Accenture for scaling our digital transformation, Palantir for data analysis, and Microsoft for our AI transformation. Data-based innovations leveraging AI facilitate collaboration between designers, engineers and customers, accelerating product development. Our digital transformation boosts our competitiveness and our capacity for innovation.

Using AI to accelerate innovation

FORVIA harnesses data and AI across its value chain, with a dedicated team and powerful tools in a company-wide program. This initiative improves decision-making and execution across R&D, Operations, and support functions. Our Palantir Foundry platform is a key asset in this domain. AI improves quality control, safety and the driving experience, with features such as hands-free trunk access and child-presence detection in unattended vehicles.

In sustainable materials engineering, AI develops predictive algorithms for adaptive formulations, ensuring stability and compliance of end products despite variations in raw materials. FORVIA also embraces generative AI solutions such as GitHub Copilot for software coding, critical in the continuous improvement of operational efficiency and product portfolio enrichment.