100% recycled and recycable

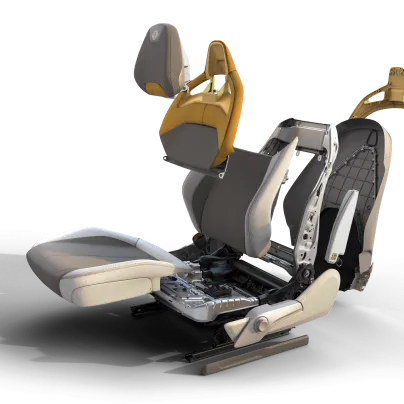

Pioneering the future of sustainable automotive textile seat covers

Circularity embodied

Bloomera's™ manufacturing process is truly circular. Thermo-mechanical recycling transforms production offcuts into PET yarn, creating a seamless loop of sustainable production. Through eco-design, each seat cover component is analyzed, paving the way for recyclable substitutes, utilizing cutting-edge recycling technology to its fullest potential.

Sustainibility with style

This innovation minimizes material variety while retaining flexibility for diverse styles. The result: next-gen seat covers with a carbon footprint nearly 25% smaller than 2019 standards, aligning with FORVIA's ambitious carbon emission reduction goals.

Total recyclability in sight

Bloomera™ marks the first step towards creating automotive textiles and seat covers from decommissioned end-of-life vehicles. By maximizing resource reuse and reducing raw material depletion, this collaboration between FORVIA, Indorama Ventures and Tesca paves the way for a new era in automotive textiles.

Key figures

Driving sustainability: closing the loop with Bloomera™

Christophe Schmitt

Executive Vice President Seating at FORVIA.

Related products