First class fit for the commercial vehicle industry

Creating a whole new Seating experience for commercial vehicles

Building on its expertise in automotive seating, and in particular its experience in seating for light commercial vehicles, FORVIA recently entered the heavy commercial vehicle seating segment. The move into this new market got off to a promising start commercially, with the signing of an initial contract last year. With its sights set on becoming a major player in this segment by 2030, FORVIA is unveiling its entire new range of seats for trucks at IAA Transportation. The new range is suitable for all types of vehicles in the commercial vehicle segment: from light commercial vehicles to medium duty and up to long-haul trucks.

A complete range of seating adapted specifically to the trucking sector

FORVIA’s seating solution for heavy-duty vehicles

This range of seat answers the needs of truck drivers who spend several days in the cabins of their heavy goods vehicles and are looking for greater comfort to enable them to carry out long journeys in the best possible conditions. FORVIA designed its seat for heavy-duty vehicles as the ultimate combination of comfort and safety, while delivering unparalleled CO2 savings. Already selected to equip tens of thousands heavy-duty trucks from 2027 onwards, FORVIA’s seat for heavy-duty vehicles offers pneumatic suspension, including fore and aft isolators, and ActiveVRS, a magnetic ride suspension system that greatly reduces vibrations for the driver.

Both the cushion and backrest are modular, meaning they can be replaced when needed, extending the lifecycle of the seat. Adjustable seatbelts are built into the frame, and premium wellness features, including massage, heating, lumbar support, and VIBE® haptic vibrations combined with sound can be offered as options. Almost all seat features are fully adjustable, including height, shoulder position, backrest bolster, and cushion length, and comfort is enhanced by ultra-premium Hycoflex foam, which acts like memory foam on a mattress. FORVIA’s commitment to lowering the CO2 footprint of vehicles can be seen here with the use of NAFILean Vision, a composite material created from various sources of biomass and recycled plastics

FORVIA’s seating solution for medium-duty vehicles

FORVIA’s seat for medium-duty vehicles has been developed to support the versatility of vehicles used in a wide range of sectors (from deliveries to construction and industrial uses). FORVIA’s expertise in comfort, derived from its long history of excellence in the automotive industry, has been decisive in providing drivers with even greater comfort. Designed as a lightweight, modular solution, it combines optimum advanced comfort and flexibility with sustainable materials to reduce the overall carbon footprint of medium-duty vehicles. FORVIA’s seat for medium-duty vehicles employs a pneumatic suspension system, with fore and aft isolators for enhanced comfort.

Modular cushion and backrest mean these parts can be easily replaced to extend the overall lifecycle of the seat. Wellness features include heating pads and lumbar massage support, with an adjustable cushion length to accommodate the widest variety of body types and offer comfort where it counts. FORVIA’s seat for medium-duty vehicles has been designed to make maximum use of sustainable materials. Padding is made using Bioflex, a foam material derived from castor oil. Seat covers are made of Ecorium, a premium alternative to animal leather made from recycled PET and hemp. MATERI’ACT’s NAFILean Vision, a composite material created from various sources of biomass and recycled plastics is also used extensively in the seat’s design, slashing its overall carbon footprint.

FORVIA’s seat for light commercial vehicles

Supplying of seats for light commercial vehicles since the early 1990s, FORVIA has drawn on its expertise to develop this range of seat and passenger bench. This seating package for commercial vehicles, comprising a driver’s seat and a passenger bench seat, is perfectly suited for short, repeated journeys made by one or more delivery drivers in the course of a single day. It also offers a reduced carbon footprint thanks to its innovative use of lightweight and recycled materials, reducing the vehicles’ overall CO2 footprint without compromising safety, quality or comfort.

The side panels of the seat feature recycled materials, which account for between 30% and 60% of their weight. The driver’s seat features a mechanical damper and a removable cover allowing easy cleaning made of FORVIA’s Bloomera™, a material for textile seat covers created from recycled production scraps. The fixed bench includes a mobile cushion and a central, foldable backrest that offers easy kinematics and storage. Its cushioning incorporates Auraloop®, a sustainable solution made from 100% recyclable polyester-based fibers with improved durability and limited subsidence over the duration of its lifetime.

FORVIA’s versatile new seating platform for commercial vehicles

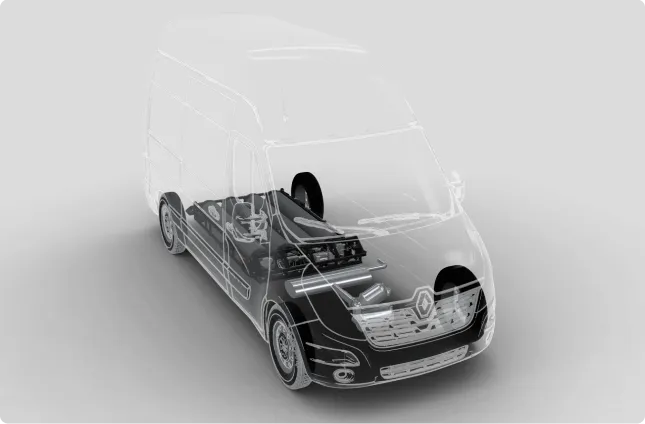

The new FORVIA truck frame is a lightweight solution offering improved CO2 performance, enhanced safety features, and versatile adjustment and suspension options. Already in production for the 2024 Renault Master van, FORVIA’s truck frame is 10% lighter than comparable truck seats on the market. The new frame was designed to embed, on demand, all our techno bricks to deliver unprecedented safety and comfort for professional drivers who spend long periods on the road.

The platform offers a wealth of options for scalable adjustments, from manual to powered, including cushion length and tilt. Its suspension systems are also scalable, with mechanical and pneumatic options, while optional belt-in-seat technology offers heightened safety with both fixed and adjustable options.

First global supplier of hydrogen storage systems for mobility

Strong measures have been taken at global level to drastically reduce CO₂ emissions and in particular to reduce CO₂ emissions from medium and heavy-duty vehicles. At FORVIA, we believe hydrogen is one of the solutions for decarbonization. Between 2030 and 2040, 30% of heavy-duty vehicles on the roads could be powered by hydrogen and we are prepared for that.

FORVIA is therefore committed to providing best-in-class hydrogen storage solutions to its customers and with serial production underway in state-of-the art facilities in South Korea, China and France, FORVIA is already the first global supplier of hydrogen storage systems for mobility. In 2023, the Group delivered 11,000 hydrogen tanks to its customers, among which Stellantis, Hyvia, SAIC, and Weichai, and is planning to scale up its production in North America, to be as close as possible to all of its customers, in the coming years.

Hydrogen storage system

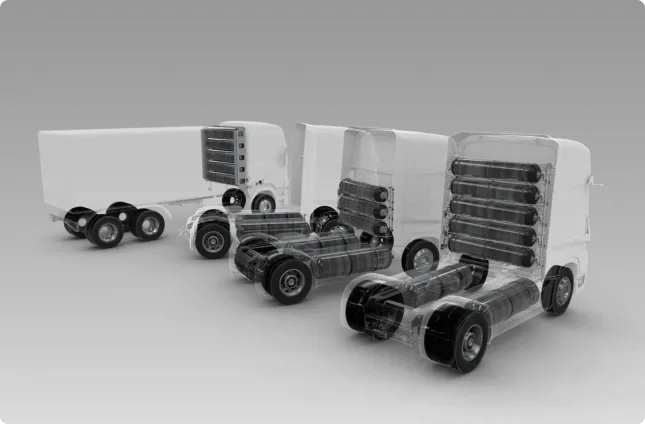

The Group developed a comprehensive range of compressed hydrogen storage solutions, which can be suitable for light commercial vehicles (LCV) as well as medium & heavy-duty and off-road vehicles, and which answer to customer’s demands in terms of vehicle integration, autonomy, reliability including demanding operating conditions.

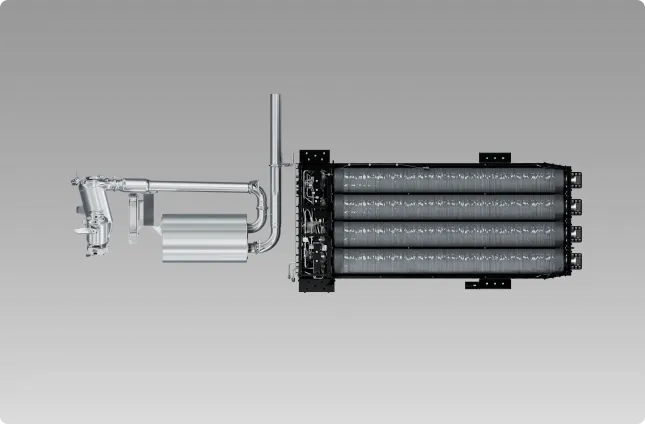

To maximize the quantity of hydrogen on board and increase the vehicle autonomy, we design and develop complex and tailored storage systems that can combine a vertical storage system installed behind the cabin module and one or more XL type IV composite tanks. Drawing on our expertise in simulation, these systems are designed for short refueling times with optimal safety.

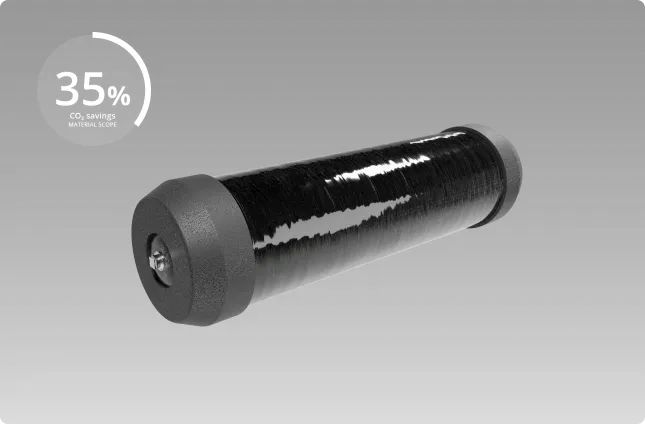

XL Gaseous tank

The FORVIA XL composite tank is a very large 70MPa high-pressure Type IV tank, and a key enabler of extended autonomy range for trucks. It can be installed in a wheelbase or cabin module. Leveraging its simulation expertise, FORVIA developed a product that offers maximized storage capacity and short refueling time under 15 min with optimal safety. Today, FORVIA is the first supplier to have certified two formats of XL Type IV composite tanks at 70MPa for mobility purposes.

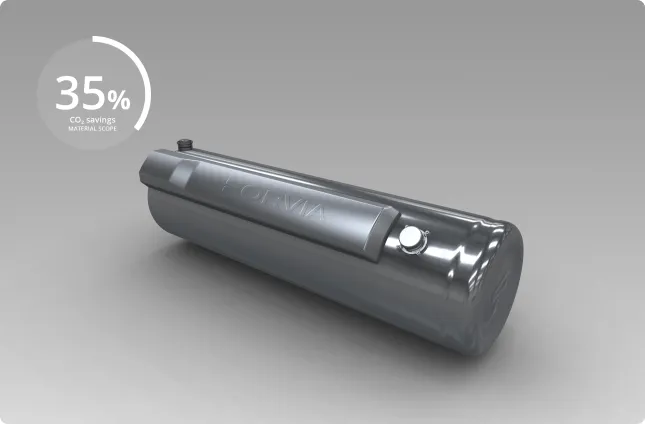

Cryogenic storage

As far as longer-term market introduction is concerned, liquid hydrogen technology is a promising storage solution.

FORVIA is developing liquid H2 tanks, for second wave market introduction, to upgrade vehicle autonomy and compactness. Cryogenic storage can achieve higher driving range compared to compressed gas at 70MPa and Battery electric vehicles at constant integration volume and is foreseen as a solution to increase the autonomy for a given space.

This hydrogen storage technology will be particularly adapted to intensive usage and will allow to reach a large autonomy of 1,000 km range milestone. Together with Air Liquide, our partner in this development, we will bring a cost-effective solution to decarbonize heavy-duty vehicles with intensive use.

Hydrogen storage solutions and aftertreatment systems for H2ICE

FORVIA is strategically positioned in aftertreatment and hydrogen storage systems, contributing to several H2 ICE R&D projects, such as the HyMot project, backed by the France 2030 investment plan, and the Southwest Research Institute's H2 ICE Demonstration Vehicle project, which aims to showcase H2 ICE's potential for near-zero emissions.

FORVIA's hydrogen storage systems offer comparable benefits for H2 ICE vehicles as they do for fuel-cell electric vehicles.

Relying on a mature technology, H2 ICE can help accelerating the widespread adoption of hydrogen mobility, fostering the growth of the hydrogen ecosystem, and refueling infrastructure. H2 ICE boasts minimal NOx emissions. The adaptable aftertreatment system can achieve ultra-low NOx levels through emissions and acoustic optimization. Leveraging expertise in exhaust and hydrogen storage systems, FORVIA delivers best in class integration that sets the industry standard.

Pioneering Technology for On- and Off-Highway Vehicles

At IAA Transportation 2024, FORVIA HELLA will be demonstrating its innovative strength for sustainable commercial vehicles. As the transformation of mobility toward autonomous driving and electromobility progresses steadily within the truck, bus, and trailer sector, FORVIA HELLA’s core competencies in lighting technology and electronics play a central role in making the future of commercial vehicles safer and more sustainable.

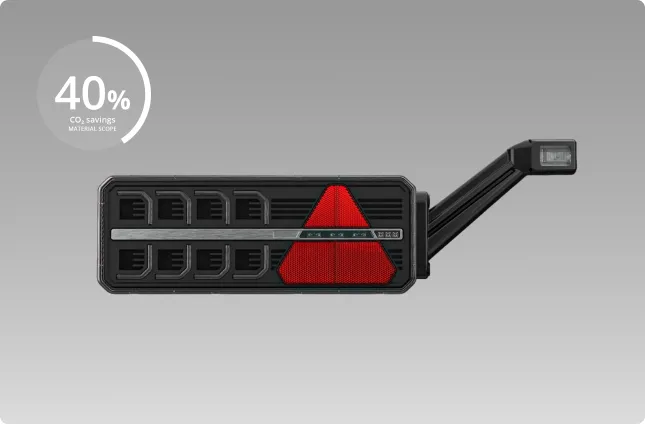

Future Trailer Lighting System makes trailers lighter, saves fuel and enables new functions

FORVIA HELLA is presenting the “Future Trailer Lighting System” as a world first at the IAA Transportation 2024 trade fair. The system’s core component is an ECU (control unit) with a CAN communication interface. This interface integrates trailer rear-lighting components, reducing cabling by saving copper and thus reducing the weight and CO2 footprint of the system.

Furthermore, digitalization enables new functionalities, like automated shunting lights and status monitoring of lighting modules. Additional sensors ensure flexibility for future requirements, making it suitable for autonomous driving. The system includes a modular, digital rear lamp with five functions, communicating via CAN bus and providing direct information to the driver’s cockpit.

Innovative modular Rear Combination Lamp Concept for trucks enables customized appearance

The customized Rear Combination Lamp Concept by FORVIA HELLA for trucks enhances road safety by displaying light-functions across a large area. Innovative LED technologies ensure high quality while reducing weight and energy consumption.

EdgeLight technology produces a far-reaching, sharply defined light signal, while LED light curtain enhanced by HELLA patented technology allows customizable logos and graphics. Additional functions, like static or dynamic direction indicators and customizable stop lights, can be adjusted via software. Manufacturers can also choose frame and bezel colors, making the Rear Combination Lamp a central eye-catcher.

Solar Sensor increases the feel-good factor in innovative cab concepts

European cities are implementing safety laws, such as the Direct Vision Standard, which requires vehicle manufacturers to eliminate blind spots using cameras or increased cabin glass. However, more glass can lead to faster cabin heating from sunlight. To enhance comfort and interior well-being, FORVIA HELLA developed the solar sensor for commercial and luxury class vehicles.

Mounted on the dashboard, it detects intense solar radiation and ensures efficient air conditioning. The sensor-supported climate control optimizes energy use. An optional ambient light detection system enhances interior brightness. The Solar Sensor communicates via a cost-effective Local Interconnect Network (LIN), reducing installation and maintenance complexity while providing stable data transmission. Overall, the Solar Sensor with LIN technology provides optimized energy management for next-generation commercial vehicles.

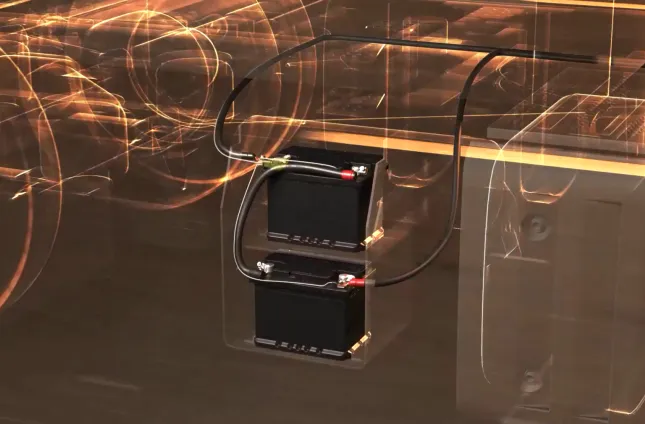

Intelligent battery sensor enables smart energy management in the vehicle

The Intelligent Battery Sensors (IBS) from FORVIA HELLA play a crucial role in centralized energy management within vehicles. These sensors contribute to CO2 reduction by enabling the start-stop function and providing essential battery data for the vehicle’s energy management system. Additionally, they enhance battery life by using their data via the ECU to prevent deep discharging and ensure optimum charging conditions.

FORVIA HELLA addresses the needs of vehicles with 24-volt architectures that require separate battery monitoring. The concept involves two intelligent 12-volt battery sensors (IBS), each dedicated to monitoring a 12-volt battery. This setup ensures precise measurement of voltage, current, and temperature parameters. The IBS offers valuable insights into battery health (state of charge, ageing and starting ability). The data can be accessed via a control panel,the on-board computer or cloud services.

Front lighting concepts for trucks reduce fuel consumption

To meet emission reduction requirements, FORVIA HELLA has redesigned product-shapes to pave the way and support new requirements regarding lighter and more aerodynamic trailers and trucks. The new slim, streamlined headlamps use highly efficient LEDs, offering longer service life and reduced maintenance.

Future headlamps may be made from sustainable materials. EdgeLight technology ensures a homogeneous light signature, creating an aesthetic appearance day and night. The innovative roofmarker above the truck’s windscreen serves as a position light, direction indicator, and high beam. Its aerodynamic shape contributes to a reduced flow resistance.